Machine Features

- BTX-200 machines operate inline with all existing

extrusion machines

·

- Process may be continuous or by batch depending

on finished products

·

- The process may be controlled by PLC or by a

computer

·

- No need for expensive and challenging moulds

·

- The mould size and shape can vary in real-time

·

- Fine-tuning of large-scale prototypes at low

costs

·

- The process saves energy by using the latent

heat of the incoming profile

·

- Labor costs for shaping profile-based products

are reduced

·

- Retooling costs are limited to cost of new shapers

for unique objects

·

- Production costs of finished products are minimal

·

- Shape of profile inner cores are preserved

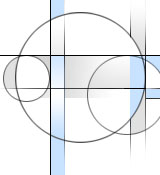

Concept of a First Generation BTX-100 BendTrusion machine for generating fixed-size products Concept of a First Generation BTX-100 BendTrusion machine for generating fixed-size products | |

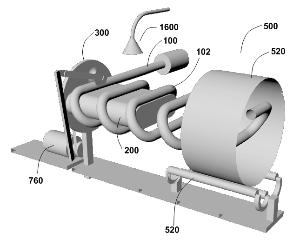

The second generation BTX-200 machine (patent pending) is based on shapers that vary their shape and position in time and space. Starting with a CAD design, a program slices the desired object into 2D contours which data prompts shapers to bend the profile in its final shape. The digital process replicates itself or may be varied in real-time. The second generation BTX-200 machine (patent pending) is based on shapers that vary their shape and position in time and space. Starting with a CAD design, a program slices the desired object into 2D contours which data prompts shapers to bend the profile in its final shape. The digital process replicates itself or may be varied in real-time. |

| | |

Finished products Features

- Innovative product shapes

made possible

·

- Finished objects may be reasonably large and

long

·

- Virtually all profile cross-sectional geometries

are possible

- The overall shape and size

of finished products may vary along their length

- Small or large production

of same or similar objects possible

- Objects may be made of

single coils of profile, e.g. loops or frames

- Spirals of variable shapes

are possible

- Coils may be interlocked

and bonded side-by-side to create hollow 3D volumes

·

- Any extrudable products such as plastic mixes (wood,

fibers, powders, etc)

·

- Extrudable organic, non-organic minerals and

food pastes can also be shaped

·

- Shaping of thin-walled metal from roll forming

machine made possible

·

- Shaping of all forms of long fibers thermoplastics

(LFT) for structural use possible

- Shaped 3D products reduce

the need for angular jointings of linear profiles of the past

|  |

U-shape profiles may be internally bended for applications such as closed frames, car chassis or aorospace applications. The same concept and technology applies for bending metal extrusions such as aluminum frames, copper or other thin and reasonably thick profiles. The cross-sectional geometry of the profile inner cores, hollow or not, is preserved during bending, no matter how complex the profile geometry is.

U-shape profiles may be internally bended for applications such as closed frames, car chassis or aorospace applications. The same concept and technology applies for bending metal extrusions such as aluminum frames, copper or other thin and reasonably thick profiles. The cross-sectional geometry of the profile inner cores, hollow or not, is preserved during bending, no matter how complex the profile geometry is.

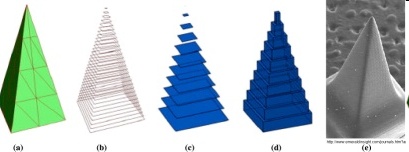

Bonding, fusing or interlocking coils of profile next to each other creates 3D products of variable shape and volume digitally controllable in Real-time.

Bonding, fusing or interlocking coils of profile next to each other creates 3D products of variable shape and volume digitally controllable in Real-time.

For any additional informtion regarding BendTrusion. please conatct sm@bendtrusion.com